1-6 of 59 results

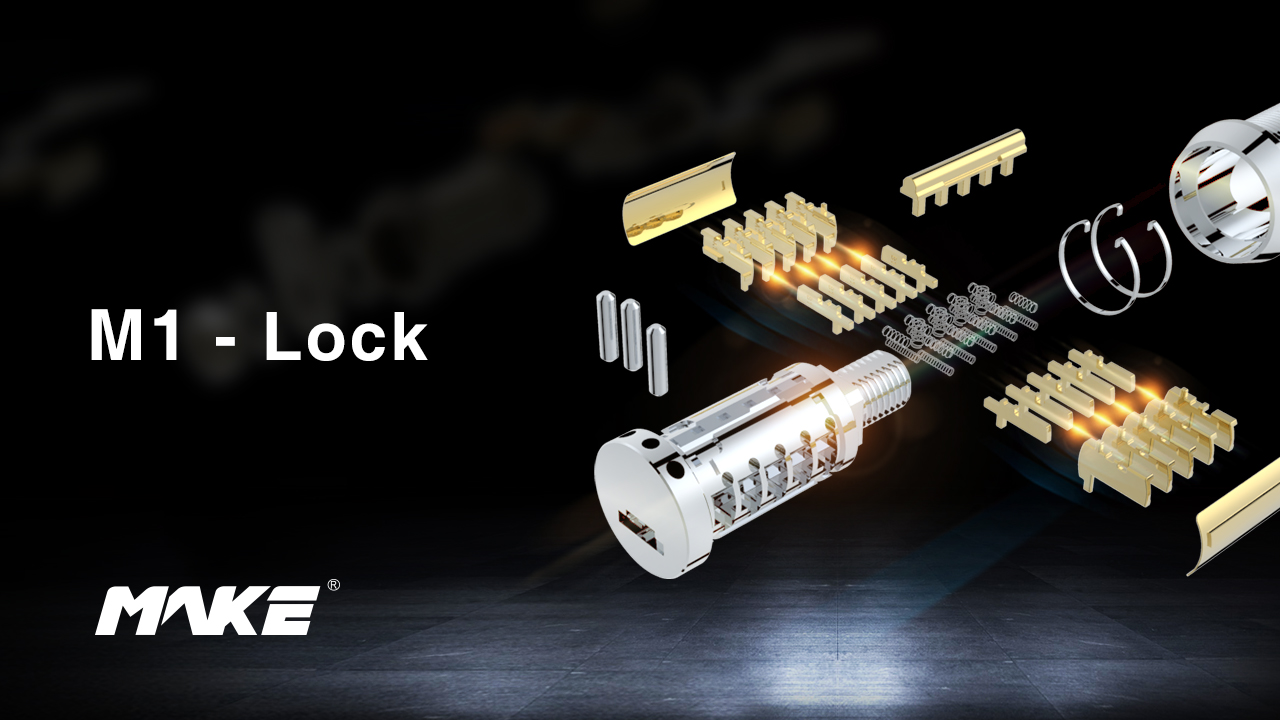

As a leading cam lock manufacturer in China, we focus on the development, design, and production of cam locks, and have launched a variety of high-security, high-quality patented cam locks, including the M1-LOCK, M3-LOCK, and M4-LOCK. These products are made from premium zinc alloy and feature high-precision stamping technology and exquisite workmanship. Our cam locks have not only passed the C-level certification issued by the Ministry of Public Security, but have also obtained patents in China, the United States, and Germany.

In simple terms, a cam lock is a fastening and locking mechanism made up of two main parts: a cylindrical body that houses the locking mechanism, and a flat rotating arm called a cam. When a key or knob turns the cam, it rotates into a secured position, usually locking or releasing a door, drawer, or access panel. The concept is simple but highly effective.

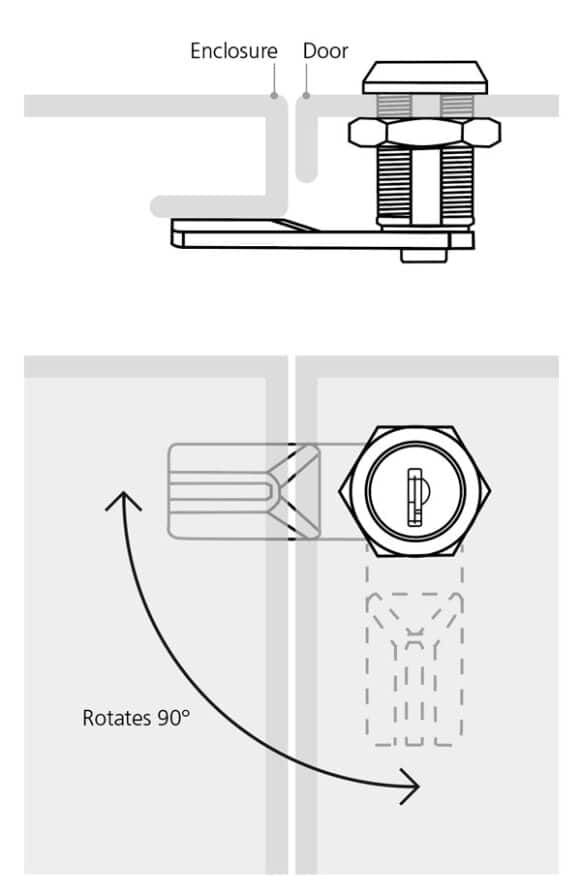

Cam locks are typically L-shaped devices that secure enclosures from the inside. Once installed, the front section of the cam lock sits flush with the surface of the door or panel, while the cam (or tongue bar) rotates behind the panel to lock or unlock the enclosure.

These cam locks can be made from various materials such as zinc alloy, stainless steel, or brass. The locking mechanism inside the cylinder varies depending on the security level required. Common cam lock mechanisms include tubular pin tumbler locks, laser-cut disc tumbler locks, or dimple-key systems.

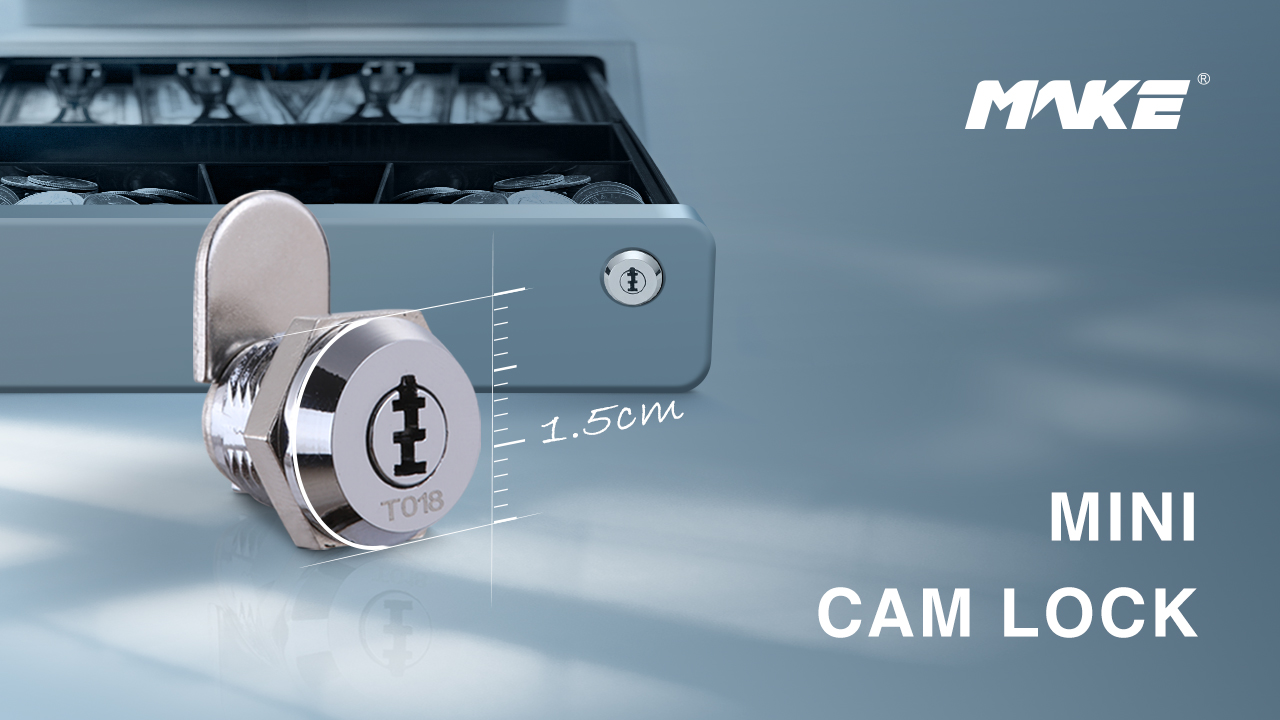

Cam locks are some of the most widely used mechanical locks in everyday environments—from mailboxes and cabinets to advanced smart terminals and industrial enclosures. Although compact in size, cam locks provide a reliable and elegant solution for securing access panels, equipment housings, and storage doors across countless industries. In this article, we will take an in-depth look at what cam locks are, how they work, and why they remain a trusted choice for both commercial and residential applications. This comprehensive guide also includes tips on choosing the right cam lock for your needs and highlights some of the key features of our cam lock product line.

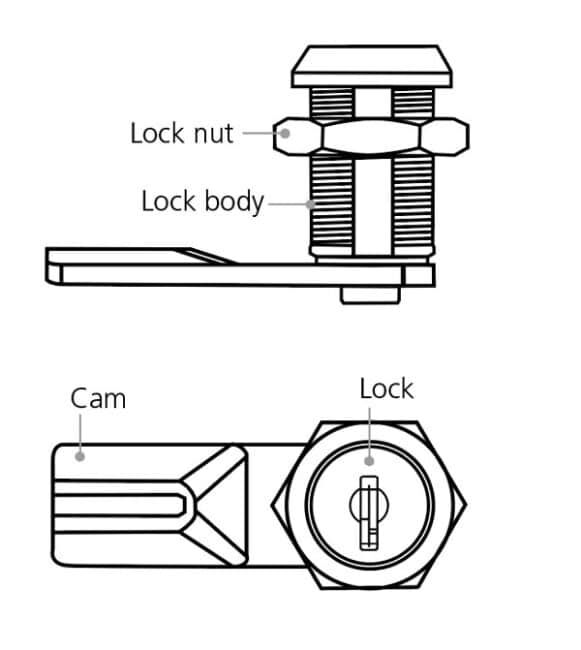

A traditional cam lock unit is composed of the following parts:

Also known as the cylinder, this is the core component. It is a threaded cylindrical housing that contains the internal locking mechanism and guides the rotation of the cam. The cam lock body is usually made of metal and is inserted through a hole or cut-out in the panel.

The lock nut is used to hold the body firmly in place from the back side of the panel. It rotates along the thread of the lock body to secure the cam lock fixture to the door.

This is a flat or bent metal plate that attaches to the end of the cam lock cylinder. When the key or knob is turned, the cam rotates into a locking or unlocking position. Different cam lengths or shapes can be selected based on the type of door or panel.

This can be a key-operated cylinder, a wing knob, a handle, a tool-access slot, or even an electronically actuated interface. For areas where high security is not a priority, ergonomic wing knobs allow tool-free access.

While cam locks come in different styles, their basic operation remains the same. The front cylinder (with key slot or knob) is installed flush to the panel. The cam remains inside the enclosure. When a key is inserted and turned, the cylinder rotates the cam 90 or 180 degrees.

When the cam is horizontal, it catches against the strike plate or frame, locking the door.

When the cam is vertical (upward or downward), it no longer obstructs the panel, allowing it to open.

Most cam locks operate on a simple quarter-turn (90°) motion, although some rotate 180° depending on design. The direction of rotation can be clockwise or counterclockwise. Once locked, the key is removed and the cam holds the enclosure securely until turned again.

Cam locks are widely used across everyday and industrial environments. They are ideal for smart terminals, financial machines, electromechanical equipment, cabinets, subway gates, kiosks, game consoles, lockers, mailboxes, and many other types of access panels commonly found in daily life.

Cam locks continue to be popular due to their practical advantages:

Quick and easy locking or unlocking with minimal effort.

With proper sealing and covers, cam locks can prevent dust or water ingress, making them suitable for outdoor or industrial use.

Operated by key, tool, knob, or handle, allowing users to choose according to ergonomic or security requirements.

Different cam lengths and offsets accommodate varying door thicknesses and latch distances.

Requires only a drilled hole and a securing nut. Installation is fast and straightforward.

To choose a cam lock that meets your needs, consider the following:

Look at the complexity of the key mechanism (number of pins/discs), the mutual opening rate (how many locks share the same code), and whether a dust cover is needed.

The tongue piece must fit the frame or door edge correctly. The length or bend determines whether the cam lock can latch securely. If the enclosure requires a stronger closure or a specific latch angle, choose the corresponding cam shape.

Make sure the cam lock barrel length matches the thickness of your panel. The lock body must fit snugly without too much protrusion.

Zinc alloy is the most popular as it offers corrosion resistance and durability at a low cost. Stainless steel is preferred for outdoor or marine environments. Brass provides a classic appearance and strong resistance to wear.

Decide whether you need:

Key lock with high security

Wing knob (tool-free access)

Tool-operated cam lock (for vandal resistance in public areas)

Combination or electronic cam lock (for smart cabinets)

The operating principle is straightforward:

Insert the key or turn the knob.

Rotate 90 degrees to engage the cam behind a strike point or latch.

The lock is secured.

Rotate back 90 degrees to release and open the door.

A simple quarter turn engages or disengages the cam against an adjacent fixed point. In more secure environments, only authorized keys can perform this action.

As a professional cam lock manufacturer and supplier in China, we offer a comprehensive range of cam locks designed to suit all types of enclosures and customer needs.

Locking Options: Keyed lock cylinders, tubular pin tumbler, disc tumbler with dimple key, laser-cut disc lock, wing knobs, tool-access heads, and even wireless or electronic options.

Materials: Zinc alloy, stainless steel (for corrosion resistance), and brass.

Surface Treatments: Chrome-plated (shiny appearance), bright zinc, powder coating (durable finish), nickel plating (anti-corrosion).

Sizes and Variants: Multiple cam lengths, thread sizes, barrel lengths, and housing dimensions.

Customization: Cam lock ODM/OEM services are available. We can produce according to your drawings or develop customized locking solutions tailored to your product line.

Cam locks are indispensable locking devices that combine simplicity, flexibility, and reliability. Whether you need a basic lock for a mailbox or a high-security tubular lock for an industrial control cabinet, cam locks remain one of the most popular solutions on the market. Thanks to their modular design, range of materials, and variety of key systems, they can be tailored to virtually any door thickness or application.

When selecting a cam lock, always pay attention to the material, cam size, door thickness, security level, and environmental conditions. For businesses that require custom branding or unique locking mechanisms, cam locks ODM/OEM are also available.

As a trusted cam lock manufacturer in China, we provide a comprehensive range of cam locks with multiple material options, surface finishes, and locking mechanisms to meet your precise requirements—backed by professional support and customization services.

Cam locks are widely used to secure cabinets, lockers, mailboxes, toolboxes, electrical panels, ATMs, and even vehicles like RVs and caravans. They provide a simple yet effective way to lock doors and access panels.

In general, a properly installed cam lock should not be easily opened without a key. However, if someone attempts to break in, they may try using a screwdriver and hammer to force the mechanism. This is why choosing a higher-security cam lock with anti-drill components and anti-pick discs is recommended for sensitive applications.

Yes. In many designs, the cam can be unscrewed from the back of the cylinder and replaced with a different length or bend to suit a different enclosure.